design services

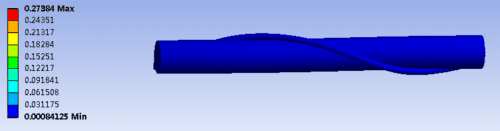

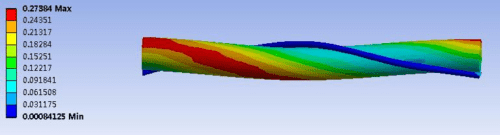

AFT USES FEA STRUCTURAL ANALYSIS FOR MODELING AUXETIC FABRIC SOLUTIONS. THIS ALLOWS AFT TO PROVIDE COMPREHENSIVE STRESS/STRAIN ANALYSIS WITH 3D MODELING, FINITE ELEMENT ANALYSIS, HYDRO NON-LINEAR IMPLICIT ANALYSIS, AND PRE- AND POST-PROCESSING FOR MODEL CONVERGENCE.

AFT PROVIDES CUSTOM DESIGN SOLUTIONS FOR VARIOUS APPLICATIONS, BUT INCREASINGLY OUR FOCUS HAS BEEN ON PROJECTS THAT ALSO PROVIDE MANUFACTURING OPPORTUNITIES FOR COMPREHENSIVE SOLUTIONS FOR OUR CUSTOMERS.

AFT UTILIZES THE FOLLOWING SOFTWARE IN ITS PROPRIETARY DESIGN:

AFT Engineering

AFT engineering utilizes specialized numerical and analytical computer models to support developmental material design and prediction of performance.

FEA Analysis

Finite Element Analysis (FEA) shows whether a product will break, wear out, or work the way it was designed. It is called analysis, but in the product development process, it is used to predict what is going to happen when the product is used.

Finite Element Analysis helps predict the behavior of products affected by many physical effects, including: mechanical stress, mechanical vibration, fatigue, motion, heat transfer, fluid flow, electrostatics and plastic injection molding to name a few.